LAN BAO

About Our Company

Shandong Lanbao Machinery Co., Ltd. was established in June 2014, covering an area of 20,000 square meters. Relying on Lanbao Machinery Research and Development Center (formerly Beijing Lanbao Machinery Co., LTD. - founded in August 2006), specializing in the production of rubber machinery equipment.The company mainly engaged in vulcanizing machine, rubber injection molding machine, injection molding machine, liquid silicone injection molding machine, liquid silicone pump material machine, plate vulcanizing machine

- VR

HOT PRODUCT

Fully Automatic Flat Vulcanizing Machine

A fully automatic flat vulcanizing machine is a specialized machine used for the vulcanization or curing of rubber sheets or strips. It is commonly used in industries such as rubber manufacturing, automotive, and conveyor belt production.Key features of a fully automatic flat vulcanizing machine…

HOT PRODUCT

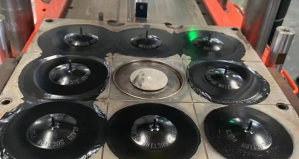

Rubber Suction Cup Injection Molding Machine

Here are a few key features and components of a typical rubber suction cup injection molding machine:Injection Unit: This part of the machine is responsible for melting and injecting the rubber material into the mold cavity.Mold: A specialized mold is used to create the desired shape and design of…

HOT PRODUCT

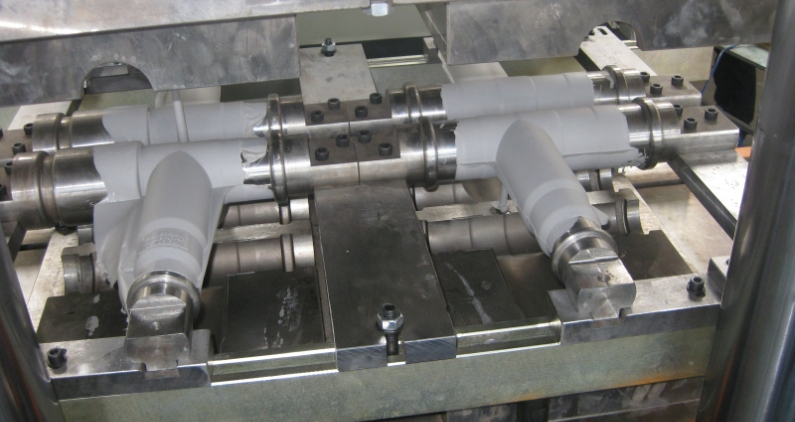

Insulator Injection Machine

An insulator injection machine is a specific type of equipment used to manufacture insulating products, such as electrical insulators or thermal insulators. It is designed to inject insulating material, such as plastic or rubber, into a mold to create the desired shape and properties of the…

HOT PRODUCT

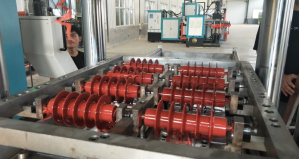

Rubber Roller Injection Molding Machine

A rubber roller injection molding machine is a specific type of injection molding machine used for the production of rubber rollers. Rubber rollers are commonly used in various industries, such as printing, packaging, textiles, and manufacturing, to provide traction, transportation, or guiding…

HOT PRODUCT

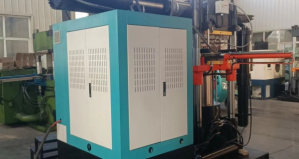

Electric Plug-in Injection Machine

An electric plug-in injection machine, also known as an electric injection molding machine, is a type of injection molding machine that operates using electric power. It is primarily used for the production of plastic parts and products in various industries, including automotive, electronics,…

HOT PRODUCT

Lightning Arrester Injection Molding Machine

A lightning arrester injection molding machine is a specialized type of injection molding machine used to produce components for lightning arresters. Lightning arresters are devices used to protect electrical equipment and structures from damage caused by lightning strikes.The injection molding…

Fully Automatic Flat Vulcanizing Machine

Rubber Suction Cup Injection Molding Machine

Insulator Injection Machine

Rubber Roller Injection Molding Machine

Electric Plug-in Injection Machine

Lightning Arrester Injection Molding Machine

GET IN TOUCH

Providing Value To Our Clients Through Ongoing Product & Innovation.

Rubber injection molding machine, referred to as rubber injection machines; a technology for the production of rubber mold pressure products. It is mainly used for the production of rubber mold pressure products, such as electrical insulation parts, shockproof pads, sealing parts, soles and water

2023-10-19

Tablet sulfur temperature control, vulcanizer is a common mechanical equipment for plastic products factories. Many manufacturers have updated production equipment. Today we will discuss the operation and temperature control instructions of the flat sulfur.Operation of the tablet vulcanizer:1. When

2023-10-19

Rubber injection is a technology for the production of rubber mold pressure products. It is mainly used for the production of rubber mold pressure products. At present, it has been widely used at home and abroad. At present, there are many types of injection machines in the world, including plunger

2023-10-19

Simplified processes to produce rubber molds, it can achieve high temperature rapid vulcanization of rubber products, shorten the production cycle, and improve production efficiency. Second: The accuracy of mechanical production is many times higher than that of manual, increasing the product's

2023-06-05

As a mechanical equipment, the rubber injection machine will inevitably fail in daily use. In order to better use and extend the service life, it should be maintained and maintained. Only in this way can cost savings and better use.The regularly maintained rubber mold wear curve exists in various

2023-10-19